OptiCool™ RT cooling technology provides the performance and reliability needed to keep platelet supplies safe and ready to use. The OptiCool™ RT system pairs a variable capacity compressor (VCC) and natural hydrocarbon (HC) refrigerants with pulse heating to:

- Ensure optimal temperature uniformity.

- Efficiently manage energy consumption and environmental conditions.

- Reduce noise output of system.

How a VCC System Optimizes Temperature Performance and Energy Efficiency

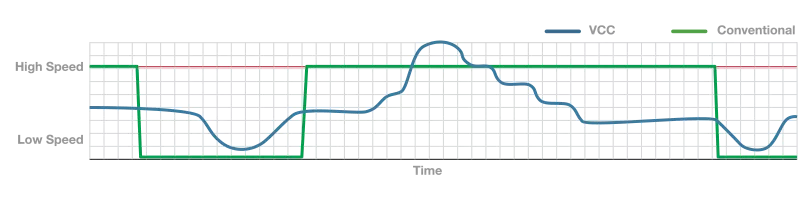

The OptiCool™ RT system uses intelligent sensors to monitor operating conditions. When the door of the incubator is opened, the VCC runs at a higher speed to deliver optimal temperature performance. When the temperature stabilizes the VCC runs at a lower speed, resulting in lower energy consumption. The heater pulses off/on to achieve the correct temperature range. Pro Line Floor Model Platelet Incubators are 75% more energy efficient than conventional platelet incubators.

Compressor Run Speed

VCCs run at variable speeds (depending on operating conditions) to maintain temperature rather than simply cycling off and on like fixed capacity compressors in conventional incubators.

Temperature Uniformity Optimized

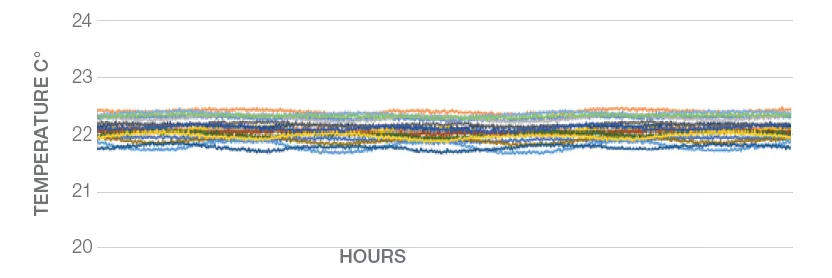

OptiCool™ RT technology optimizes temperature uniformity for safe platelet storage and other applications that require room-temperature storage. Pro Line models have precision temperature controls and temperature uniformity of +/- 1°C, providing a consistent room temperature storage environment.

At an operating set point of 22°C, these models maintain a consistent room temperature storage environment between 20-24°C, thus ensuring your platelet products will not be compromised by temperature excursions.

Demonstrated Uniformity with Pro Line Incubators

PC2200-Pro with (2) PF96-Pro Agitators, 22° Set Point

With a continuous operating temperature of 22°C and temperature uniformity of +/-1°C, the Pro Line offers a stable storage environment.

Energy Savings and Reduced Operating Costs

OptiCool™ RT technology significantly reduces energy usage. Pro Line incubators are over 75% more energy efficient than traditional incubators. The use of natural hydrocarbons in the system:

- Reduce heat output

- Decrease carbon footprint

- Reduce the overall cost of ownership

Energy use by Helmer Scientific Pro Line models is over 75% lower than traditional incubators, reducing total cost of ownership.

Using an average energy rate of $0.1279/kWh*, that's an annual savings of up to $700 per unit.

*Based on U.S. Energy Information Administration, commercial sector, Jan 2023

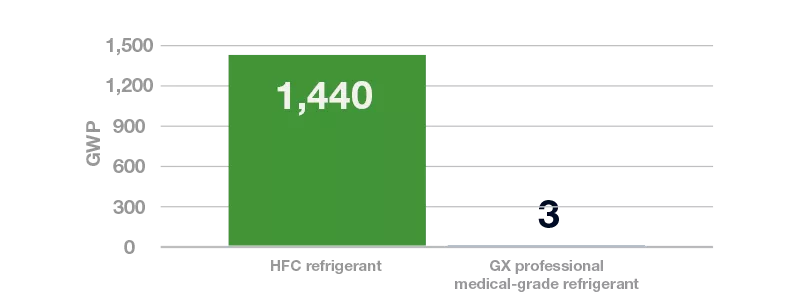

Natural Refrigerants (HCs) Support Environmental Sustainability

Pro Line Floor Model Platelet Incubators use R600a, a naturally occurring refrigerant that helps meet environmental standards.

- Environmental Protection Agency (EPA), Significant New Alternatives Policy (SNAP), Montreal Protocol, Paris Climate Agreement, and EU F-Gas compliant

- No impact on ozone depletion

- Very low Global Warming Potential (GWP)

Global Warming Potential of Used Refrigerant

Pro Line Floor Model Brochure

Learn more about Pro Line floor model platelet incubators