Hancock Physician’s Network (HPN) in Greenfield, IN continues to raise the bar in driving quality and efficiency improvements within their vaccine administration program. The Network is multi-disciplinary and includes family, pediatric, internal medicine and immediate care practices, all which use and store vaccine. These locations are storing anywhere from three to 20 different types of vaccines. The family practice locations alone are storing 20 different vaccines on average with at least 10-20 doses of each. Two of the family practices as well as the pediatric location, are Vaccines for Children (VFC) providers.

The Cost of Discarded Vaccines

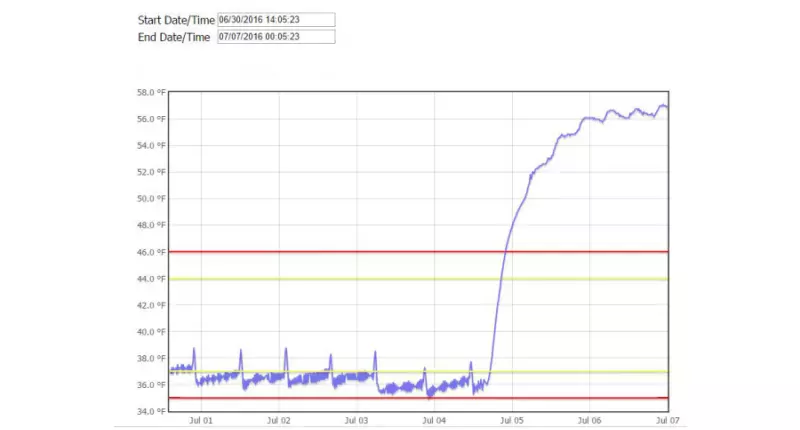

In a 2014, HPN experienced a power outage at one of the family practice sites. After the power outage, the process to verify whether vaccines needed to be discarded because of the temperature excursion was tedious and time consuming. Multiple doses of vaccines had to be discarded due to loss of potency from the temperature excursion. This power outage was very costly to the Network. An even more devastating vaccine loss occurred July of 2016 at a different HPN family practice where they were storing vaccines in a household refrigerator. The refrigerator failed over the 4th of July holiday weekend, as shown in the graph below, resulting in a several thousand dollar loss. Had this failure occurred at the pediatric location the cost of the loss would have been significantly higher due to the number of vaccine stored at this practice.

The HPN Operations Team determined loss of costly vaccines was a wakeup call. Not only are these vaccines expensive, they are an essential part of protecting the community against preventable disease. After the two losses it was realized that the Network needed to focus on strengthening the vaccine program in order to provide patients with the highest level of care.

Improving the HPN Vaccine Program

With the goal of standardizing and optimizing the vaccine program across the Network to provide the highest level of patient care, HPN turned to the Vaccine for Children Program (VFC) guidelines for direction. The VFC program strictly prohibits the use of dormitory style refrigerators for the storage of vaccines. In addition, VFC vaccines must be stored in a refrigerator/freezer which is monitored with a continuous temperature monitoring device such as a data logger or wireless monitoring solution. All providers entering into the VFC program today must store their VFC vaccines in medical-grade refrigerators. HPN has determined that all sites will store vaccines according to VFC guidelines, regardless if the sites are VFC providers. This ensures the highest level of safety and patient care. HPN feels very strongly that all of their private vaccines should be properly stored and monitored exactly the same as way as their VFC vaccines. If not, they would be creating a double standard of care. Every patient deserves vaccines that are stored, monitored, and handled appropriately. HPN set forth by implementing a multi-pronged approach to revitalize the vaccine program. The plan consisted of temperature monitoring, medical-grade refrigeration, and strengthened processes to ensure every vaccine, whether it was VFC or private stock, was being handling efficiently and effectively.

Implement Temperature Monitoring > Switch to Medical-grade Refrigeration > Strengthen Processes > Inform Update & Train Staff > Monitor & Manage Program

Temperature Monitoring & Notifications

To safeguard the vaccines and meet VFC requirements related to continuous temperature monitoring, the network outfitted all of their vaccine refrigerators and freezers with Sonicu wireless temperature monitoring devices.

Sonicu’s platform allows HPN staff to monitor and manage all refrigerator and freezer temperature data with 24/7/365 text and email alarming to Internet-based devices of their choice. The next step was to develop a 24 hour alarm coverage program/protocol. This program is set to launch in January 2017.

The Power of Data

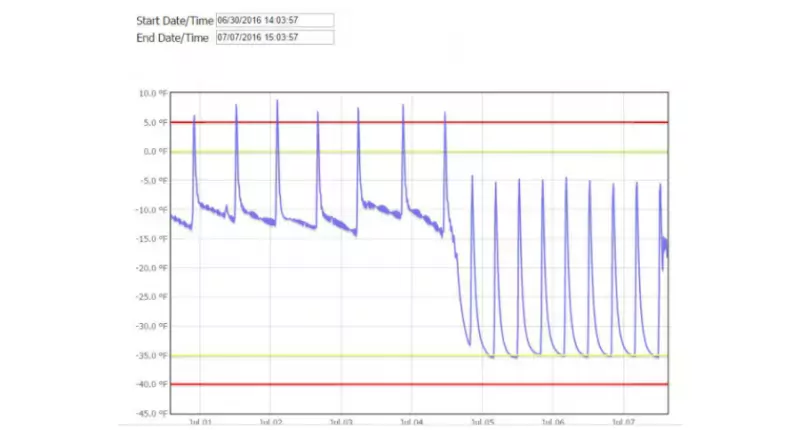

After implementing Sonicu, HPN had the data to highlight the poor temperature stability of the household refrigerators storing vaccines, which strongly supported the case to move to medical-grade refrigeration at all locations. Data collected from the various household refrigerators and freezers proved that the units were not performing well enough to meet recommended storage conditions.

HPN then used the historical temperature data available from their Sonicu platform to draw out a plan for replacing the vaccine refrigerators and freezers by analyzing their level of temperature stability. The most unstable units were replaced immediately and every refrigerator and freezer, whether it is household or medical-grade, continues to be monitored to ensure vaccine efficacy and patient safety. Alarms and notifications keep the staff informed and prepared to handle emergencies if vaccines are at risk of a temperature excursion.

Medical-grade Cold Storage

With data to support the transition to medical-grade refrigeration, HPN began evaluating various cold storage companies. Helmer Scientific refrigerators and freezers were chosen due to the company’s strong reputation and commitment to quality and reliability for the safe storage of vaccines. HPN valued that the company was based in Noblesville, Indiana, just a short drive from the Network’s various locations.

Within months, the Network phased out 75% of their household units and standardized with Helmer medical-grade refrigerators and freezers. HPN will continue this process until all household units have been replaced. The shocking difference in stability between the household units and the Helmer Scientific medical-grade units is demonstrated in the graphs below.

Standardizing on cold-storage has provided HPN with numerous benefits, such as higher product quality, exceptional customer service, and increased efficiencies when it comes to managing and maintaining the equipment. The changes have all been well received and physicians, nurses and staff have taken notice that HPN is committed are to providing the best patient care as possible.

Continuing the Journey

With temperature monitoring in place and the transition to 100% medical-grade refrigeration underway, HPN, is taking time to look at processes and procedures around the vaccine program. Once these updates have been solidified they will be rolled out to the staff members who will undergo additional training. With top level support, HPN is making substantial progress into the Network’s vaccine program to safeguard vaccines, diminish waste, streamline processes, and keep the community safe from preventable disease.

HPN is very pleased with their implementation progress and through their relationship with Helmer Scientific and Sonicu, they can be assured that all of their vaccines are continuously monitored and stored under appropriate conditions in order to provide safe and effective patient care to our community.

Conclusion

Health networks across the country are in various stages of making these changes to better monitor and manage their vaccine programs. Providing the level of patient care demanded by the VFC program takes tremendous effort, resources, and financial investment. The organizations that choose to make these changes in continuous temperature monitoring and medical-grade refrigeration will quickly recover their investment by protecting their valuable and expensive vaccines. More importantly, these networks will help ensure that they are providing their communities safe and effective vaccinations for the fight against preventable disease.